Job Title: Radiographer, Instructor

Plant: Y-12, X-10

Years Employed: 1954-2008

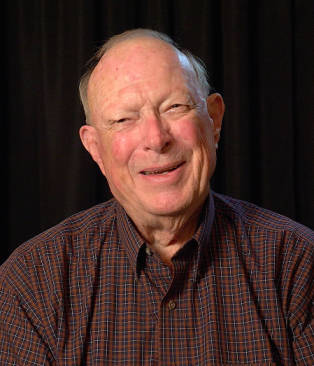

MCDANIEL: This is Keith McDaniel, and today is June the 4th, 2017, and I am at my studio here in Oak Ridge with Mr. Benny Houser. Mr. Houser, thank you for coming by and talking with us.

HOUSER: Thank you very much for the invitation. I appreciate that.

MCDANIEL: Sure. Well, let’s start at the very beginning, your very beginning. Tell me where you were born and raised, something about your family.

HOUSER: Well, I was born November the 18th, 1935, in a little community off of Chapman Highway, between Knoxville and Seymour, called Neubert Springs. My grandfather and grandmother lived there, and several of my immediate relatives. My grandpa had 13 children and a big farm.

MCDANIEL: Yeah.

HOUSER: Grandpa was a truck farmer, came to Knoxville each Saturday and sold produce on Market Square. My dad taught at several schools in that area in the beginning, and then in 1940, he got a job as an accountant with Alcoa, the Aluminum Company of America, and we moved there.

MCDANIEL: In 1940?

HOUSER: Yes.

MCDANIEL: Okay.

HOUSER: I went to school in Alcoa at Springbrook Grammar School for eight years. After I’d finished my eighth year, Alcoa was in the process of building a facility in Port Lavaca, Texas, and my dad was transferred out there, so my mom and I moved out there with him, and I went to high school my first two years there in Port Lavaca, Texas.

MCDANIEL: Now, were you the only child?

HOUSER: Yes.

MCDANIEL: Okay.

HOUSER: I’m the only child.

MCDANIEL: Okay. All right. Your first two years of high school?

HOUSER: Yes.

MCDANIEL: Now, where is that in Texas?

HOUSER: It’s about halfway between Corpus Christie and Galveston, on the coast.

MCDANIEL: Oh, yeah.

HOUSER: Alcoa had some gas wells out in the gulf, and wanted to utilize gas for their facility out there, dealing with aluminum. Mother and Daddy both are from East Tennessee, and we seemed to be misplaced out there, but Dad got a job offer at the Y-12 facility, and we moved back to East Tennessee in 1951.

MCDANIEL: Oh, okay. All right.

HOUSER: For three months, we lived with my grandmother in Lafollette, and I rode back and forth with Dad. I would get out of the car in front of the Central Bus Station and catch a ride with a friend to the new Oak Ridge High School. I was in the first group to attend the new Oak Ridge High School.

MCDANIEL: Of what we would call the new school.

HOUSER: That’s correct.

MCDANIEL: Right, right.

HOUSER: I finished my last two years in high school there and graduated from Oak Ridge High School in 1953.

MCDANIEL: Now, what did your dad do at Y-12? Was he an accountant?

HOUSER: He was a building engineer.

MCDANIEL: Oh, is that right?

HOUSER: Yes.

MCDANIEL: Okay. All right. Huh. All right.

HOUSER: I made the decision that I’d go to college at Tennessee Weslyan, but I didn’t fit in real well down there I guess. I didn’t really enjoy the college environment, so after the first year, I decided I had gone about all I needed to go.

MCDANIEL: Right.

HOUSER: I came back to Oak Ridge and ended up getting an offer at the Y-12 facility in the nondestructive testing group, and went to work there October the 10th, 1954.

MCDANIEL: You went for a year to college, and it wasn’t a good fit.

HOUSER: At that time.

MCDANIEL: At that time, right.

HOUSER: Yes.

MCDANIEL: Right, right. Did you know what you wanted to do? I mean, did you have any specific interests in high school?

HOUSER: Well, I had some interests, but they weren’t the type that I felt like I needed to try to make a living at. I liked automobiles and mechanical things and so forth, but I got into an organization, primarily radiography, and a couple of years of that and I began to realize that we were doing things that nobody in the world had ever done, in the way of radiography, and took a significant interest in that discipline.

MCDANIEL: What is radiography?

HOUSER: It’s making radiographs of materials using x-rays of isotopes.

MCDANIEL: Uh-huh, sure.

HOUSER: Various types of materials, and you can imagine what those materials were at Y-12.

MCDANIEL: Right. Sure. What were you looking for, defects?

HOUSER: We were looking for discontinuities in materials.

MCDANIEL: Right.

HOUSER: These were components, if you want to look at it from that perspective.

MCDANIEL: Right.

HOUSER: Yes. I began to take a sincere interest in nondestructive testing, and learned a lot on my own. I was in that department for 19 years, while I was at Y-12. But the last four years, I spent as an instructor at the Training and Technology [TAT] Program.

MCDANIEL: Oh, is that right?

HOUSER: Yes.

MCDANIEL: TAT, TAT. TAT, yeah.

HOUSER: I managed the Nondestructive Testing Program there, and taught students technical information during the afternoons. Oak Ridge Associated Universities ran the academic program in the morning.

MCDANIEL: Right, right.

HOUSER: Taught students in the morning.

MCDANIEL: Well, tell me about TAT. Tell me … There may be some people that are listening that don’t know what TAT was.

HOUSER: Well, it’s a program entitled Training and Technology, and it was sponsored by the Department of Health, Education, and Welfare, the facilities were funded by DOE [Department of Energy], of course, and then the technical instruction and the equipment was furnished by Y-12. The academic training was furnished by instructors from Oak Ridge Associated Universities, and the program was managed by a fellow by the name of Ralph Pearson, a Union Carbide employee then.

MCDANIEL: What were some of the disciplines, some of the areas of study, and who would be like a typical student, and what was kind of the purpose?

HOUSER: Well, the purpose of the program was to train unemployed or underemployed people.

MCDANIEL: In technical fields.

HOUSER: In technical areas. We offered Nondestructive Testing, Welding, Chemical Operations, Graphics, and Machining.

MCDANIEL: Right, right.

HOUSER: The training program was six months in length, and if the students that were recruited didn’t live here in this immediate area, they were paid a stipend to live in the dormitories in Oak Ridge, and furnished bus transportation back and forth to school, and money for their meals and so forth.

MCDANIEL: Sure.

HOUSER: The program was six months each time it was offered …

MCDANIEL: Yeah.

HOUSER: Eight hours a day, five days a week. We trained them in understanding what it meant to be an employee and have responsibility. Some of the students didn’t fit in real well in the beginning, until they began to realize the value of the program.

MCDANIEL: Right.

HOUSER: Then.

MCDANIEL: Not to linger on that, but I mean, it was really one of the first job training efforts for technical people in this area.

HOUSER: That’s correct.

MCDANIEL: It really was.

HOUSER: I would say our placement, during the program was 98%.

MCDANIEL: Yeah.

HOUSER: About 98%.

MCDANIEL: Right, right.

HOUSER: My Department Manager in Y-12, one time, offered all 25 of our students a job.

MCDANIEL: Yeah.

HOUSER: We had a company out in Memphis call me and said if I would focus a little more on ultrasonics for this next program coming up, they would hire every one of our students.

MCDANIEL: Is that right?

HOUSER: Chicago Bridge and Iron, they helped me design the program to meet their needs.

MCDANIEL: Sure.

HOUSER: Then, at the end of the program, they fulfilled their word and offered each one of the students a job. Some of them chose not to go …

MCDANIEL: Sure, sure.

HOUSER: But we’ve had several students that went through the program do very well. One of them I’m aware of ended up as Manager of Welding at Y-12.

MCDANIEL: Is that right?

HOUSER: TVA [Tennessee Valley Authority] hired a lot of our students, but there was a significant number hired by the Y-12 organization also.

MCDANIEL: Which was good for Y-12, to support that, because they were getting trained employees out of it.

HOUSER: That’s correct.

MCDANIEL: They were being trained the way they wanted them to be trained.

HOUSER: That’s exactly right. That’s a good point.

MCDANIEL: Yeah.

HOUSER: We even went so far as to teach skills that you wouldn’t imagine being taught there. We taught employees how to interview, how to shake hands, how to look the interviewer in the eye …

MCDANIEL: Is that right?

HOUSER: And speak. Oh, yes. We spent several days, during the last few weeks of the program, teaching them how to conduct themselves. We looked at things, as the course went on, from the beginning to the end, at their attendance, and their attentiveness, their abilities to learn and understand, and so forth, and interest in the program. It was amazing to see the transition of some of these students, and what they went on to make of themselves years later.

MCDANIEL: Were these young people, mostly, or …?

HOUSER: The majority of the people were probably 25, 28 years old.

MCDANIEL: They had probably not had much opportunity in their life …

HOUSER: That’s correct.

MCDANIEL: Did they?

HOUSER: Exactly right, they were doing menial work, labor work, and so forth. Now, if a young individual had the money, and wanted to go, they could pay their way through the program.

MCDANIEL: Oh, is that right?

HOUSER: We had several people from the Oak Ridge area do that.

MCDANIEL: Okay.

HOUSER: It was a really well-run program. If people didn’t show up on Monday morning, or any morning, we would investigate why, and help them understand the need to be there on time, and how to conduct themselves in our training sessions and in our work activities in the afternoon. Things that made into a good employee.

MCDANIEL: What … You said it ran for about 18 years.

HOUSER: Yeah.

MCDANIEL: What was the timeframe in that? Was that the ’80s?

HOUSER: No. It started about ’62 …

MCDANIEL: Oh, okay.

HOUSER: To ’80 …

MCDANIEL: ’80?

HOUSER: ’80.

MCDANIEL: Okay. And the reason it stopped was, did it just, lose funding for it?

HOUSER: I have no idea. Lots of us have often wondered that. Of course, I had moved on. I left there in ’69. Actually, it was closed before I realized it, but, and I don’t know the reason why, but it was a very successful program from several people’s viewpoint.

MCDANIEL: I’m going to do something real quick, and …

HOUSER: Okay.

MCDANIEL: Then we’ll continue on.

HOUSER: All right.

MCDANIEL: Sometimes I have to make an adjustment. There we go. Yeah, it’s … It really was one of the, it really was a forerunner of a kind of some of the technical training programs that they have now. There’s such a big push for technical training, like in community colleges and things such as that, for specific technical jobs.

HOUSER: That’s exactly right, and we pursued a program that would get the individuals ready to go to work in our lab at Y-12, and we felt like if they could meet our requirements, they could meet most any requirements in the country.

MCDANIEL: Sure, exactly.

HOUSER: That’s how we set our program up, and it …

MCDANIEL: Now, was that a full time … That was a, was that a full time job for you?

HOUSER: Yes.

MCDANIEL: Okay, and you said that the programs lasted for six months. Did they do two of those a year, or …?

HOUSER: Yes.

MCDANIEL: Oh, okay. Yeah. All right. Do you remember how many students would be in the program at a particular time?

HOUSER: Well, I don’t know about the entire program. Most of the classes had 20 to 24 students …

MCDANIEL: Oh, okay, so …

HOUSER: Not much more than that.

MCDANIEL: A hundred or, probably a hundred or so at a time, wasn’t it?

HOUSER: Yeah.

MCDANIEL: You said you did that for the last four years of your radiography department?

HOUSER: Of my stint there at Y-12.

MCDANIEL: Yeah, yeah.

HOUSER: Yes.

MCDANIEL: Yeah.

HOUSER: I should inject here, I guess, that when I went to TAT, I ran into my former scout master at Alcoa.

MCDANIEL: Is that right?

HOUSER: He was, the University of Tennessee had a part of that program there, also, where veterans could come.

MCDANIEL: Oh, okay. All right.

HOUSER: During a conversation with Dr. Don Brown, he was aware of my formal education, he said, “Benny, you need to go back to school and get your degree.”

MCDANIEL: Okay.

HOUSER: I enrolled at night school, primarily, here in Oak Ridge, and finished my degree in five years, and I’m really proud of that. That’s probably one of the best things I’ve done.

MCDANIEL: From UT?

HOUSER: Yes.

MCDANIEL: Okay, and they offered night school here in Oak Ridge?

HOUSER: Yes.

MCDANIEL: Okay.

HOUSER: I also took some correspondence classes.

MCDANIEL: Mm-hmm. Sure.

HOUSER: Lots of them.

MCDANIEL: Today they’d call those online courses.

HOUSER: Yeah, that’s correct.

MCDANIEL: So what did you get your degree in?

HOUSER: Industrial engineering.

MCDANIEL: Oh, industrial engineering.

HOUSER: Yeah.

MCDANIEL: Now, how old were you when you got your degree?

HOUSER: Oh, 36.

MCDANIEL: 36? Well, you were still a young man. You still had a lot of time ahead of you.

HOUSER: Yeah.

MCDANIEL: That was while you were in the Nondestructive Testing Department.

HOUSER: Yes.

MCDANIEL: Program there at Y-12. Okay. All right. Good. Once the TAT stuff was done, what did you do next?

HOUSER: They put in place a program at K-25, and you may have heard of it, CIP CUP.

MCDANIEL: Okay.

HOUSER: They …

MCDANIEL: CIP CUP? How do you spell that?

HOUSER: Cascade Improvement Program, Cascade Upgrading Program.

MCDANIEL: Right, exactly.

HOUSER: They upgraded the three gaseous diffusion plants here in the United States at Oak Ridge, Paducah, and Portsmouth.

MCDANIEL: Right.That was a huge, huge project.

HOUSER: That’s correct. It was about 11 years long, and I want to say over a billion dollars in cost.

MCDANIEL: I think you’re right.

HOUSER: Replacing components for the three gaseous diffusion plants was the objective.

MCDANIEL: Sure.

HOUSER: They invited several of us from Y-12 and formed a group of inspection engineers, and we were responsible for assuring the quality of the components that were being manufactured around the United States.

MCDANIEL: Oh, okay.

HOUSER: As you might expect, all of us in that group traveled the majority of time, and I managed the group that were responsible for all the products that were produced in the east and northern parts of the United States.

MCDANIEL: Okay.

HOUSER: I was averaging about 50 trips a year.

MCDANIEL: Wow.

HOUSER: Even though I was supervisor, I still visited the areas where I had people working, or if we had something occur and didn’t have the employees, I would fill in myself.

MCDANIEL: Now, let me stop you there and ask you a question. You said you were responsible for making sure the quality control of the components that were being produced.

HOUSER: That’s correct.

MCDANIEL: Is that the components that would go into the cascade, like the pumps and pipes and electronics?

HOUSER: The converter and other parts that were nickel plated.

MCDANIEL: The converter?

HOUSER: Yes.

MCDANIEL: Right, right.

HOUSER: The components that went into making it.

MCDANIEL: Right, exactly.

HOUSER: I thinks it’s important that you understand everything inside that equipment, that uranium hexafluoride came in contact with …

MCDANIEL: Right.

HOUSER: Had to be nickel-plated.

MCDANIEL: Everything had to be nickel-plated, absolutely.

HOUSER: The only plating facility in the United States big enough to handle those components was Huntington Plating in Huntington, West Virginia.

MCDANIEL: Well, I was going to ask you, where did you have to go a lot, because I figured there were very few places that had the capability of doing what needed to be done.

HOUSER: That’s correct. Then, the two facilities moved to Oak Ridge from California and the government built two big plating facilities here in Oak Ridge, Pathway Bellows and Jet Air.

MCDANIEL: Right.

HOUSER: To ensure that they had plenty of plating work to do.

MCDANIEL: Sure.

HOUSER: I did that for 10 years. Then the centrifuge program was kind of moving from research to development, and they asked me to join the centrifuge program, which I did.

MCDANIEL: Out at K-25.

HOUSER: Out at K-25. They built a Centrifuge Plant Demonstration Facility, the big, tall building there.

MCDANIEL: Sure.

HOUSER: I was the quality engineer on that facility from the time we poured concrete until the time they put the centrifuges in it to operate.

MCDANIEL: Now, was this before the big showdown with AVLIS [atomic vapor laser isotope separation], right?

HOUSER: Well, AVLIS was occurring some during this period …

MCDANIEL: Right.

HOUSER: Out on the West Coast, I believe.

MCDANIEL: Right, right.

HOUSER: Yeah, but anyway, the decision was made to use the centrifuge design that they had. Actually, some of our people, including me at times, would visit some of the contractors around the United States building centrifuges for the government.

MCDANIEL: Is that right?

HOUSER: The government, once they decided on the final design, selected three companies to make centrifuges for the facility that was being built in Portsmouth, Ohio.

MCDANIEL: Right.

HOUSER: Goodyear Aerospace in Akron, Ohio, home of the blimp …

MCDANIEL: Right.

HOUSER: Garret AiResearch in Redondo Beach, California, and Boeing.

MCDANIEL: Right.

HOUSER: Boeing bought land here in Oak Ridge, and built their centrifuge manufacturing facility here.

MCDANIEL: Oh, okay.

HOUSER: All three companies went through what we call a tool made sample inspection program, where we actually watched them, each facility, for three months, make the first five centrifuges. We watched every procedure, and if they needed to change it, the changes were made during that time, to the point that all the people involved were comfortable that the procedures were adequate to assure a good quality component.

MCDANIEL: Yeah. Now, let me ask you a question. Those centrifuges that they were building, I guess, sort of on spec …

HOUSER: Yes.

MCDANIEL: So to speak … These were big, right? I mean, they were …

HOUSER: Yes, they were roughly 24 inches in diameter, 20 feet in length.

MCDANIEL: That’s what I was thinking. They were good sized.

HOUSER: They were operated inside a half-inch steel casing …

MCDANIEL: Right, right.

HOUSER: To contain the centrifuges that would periodically, would quote “wreck.”

MCDANIEL: That would keep it from blowing apart?

HOUSER: Well, it would blow apart, and that’s what the cylinder was for.

MCDANIEL: That’s what I mean.

HOUSER: Yes.

MCDANIEL: The cylinder would keep it contained.

HOUSER: To contain any uranium hexafluoride gas, and the components themselves.

MCDANIEL: Exactly.

HOUSER: It was not unusual as they were being driven up to speed, one might not be balanced exactly right, and as they would go through a critical vibration and so forth, they would blow apart (wreck).

MCDANIEL: Sure.

HOUSER: It was not unusual.

MCDANIEL: You don’t want that …

HOUSER: No.

MCDANIEL: Blowing apart, not only because of the flying debris, but because of the contamination.

HOUSER: Exactly, and having to deal with it and clean it up, and then the money, too, you know.

MCDANIEL: Sure, sure.

HOUSER: Those were pretty expensive pieces of equipment.

MCDANIEL: Yeah.

HOUSER: They began to ship them to Portsmouth, Ohio, and put them in the facility there, and began to rotate them. They never put any on gas. This is ’84, late ’84. In January of ’85, when, I believe it was [President Ronald] Reagan, canceled the centrifuge program and the gaseous diffusion program.

MCDANIEL: Right.

HOUSER: If you look at the market and the nuclear program as a whole, it was about at its lowest point at that time.

MCDANIEL: Sure, sure.

HOUSER: We didn’t need uranium. Also, a little bit later, we entered into a program with Russia, Megatons to Megawatts, where they would take their nuclear weapons, disassemble them and machine them into filings, and then sell the filings to us, and we would down blend them from a 90% uranium to 6% uranium, for nuclear fuel.

MCDANIEL: Right, exactly.

HOUSER: For 20 years, the majority of the energy in the U.S. nuclear reactors came from Russian-made weapons.

MCDANIEL: Going back to the facility in Dayton, Ohio, it never was operational.

HOUSER: Yeah. Portsmouth.

MCDANIEL: Ports- that what I meant, Portsmouth.

HOUSER: That’s correct.

MCDANIEL: In Portsmouth.

HOUSER: They never put any centrifuges on gas …

MCDANIEL: Right.

HOUSER: And …

MCDANIEL: When you mean by gas, you mean …

HOUSER: Uranium …

MCDANIEL: Uranium …

HOUSER: Uranium hexafluoride gas.

MCDANIEL: Hexafluoride, which was the gas that was used for the uranium separation.

HOUSER: That’s correct.

MCDANIEL: Sure.

HOUSER: They shut everything down and removed the centrifuges and sent them back to the manufacturers to destroy.

MCDANIEL: Okay.

HOUSER: That was the end … They turned that building into a warehouse.

MCDANIEL: That was the end of the centrifuge program, wasn’t it?

HOUSER: That’s correct.

MCDANIEL: My goodness.

HOUSER: Until later on.

MCDANIEL: Yeah, until later on. Right, exactly.

HOUSER: Later on, a company was formed, the United States Enrichment Corporation, to do some new research in the centrifuge, and they bought the Boeing facility, and as you’re probably aware of, had quite a number of people working over there, and …

MCDANIEL: Right.

HOUSER: The money became very difficult to come by, and I understand the facility is setting there with not much going on right now …

MCDANIEL: Yeah.

HOUSER: As we speak.

MCDANIEL: Like you said, in ’85, that whole mid-80s thing, was probably the lowest point for the nuclear industry …

HOUSER: That’s correct.

MCDANIEL: In the U.S., that was also the time that they shut down K-25, and all, the enrichment process …

HOUSER: In Paducah …

MCDANIEL: In Paducah …

HOUSER: And Portsmouth.

MCDANIEL: And Portsmouth, yeah. They shut them all down. What was their reasoning for that?

HOUSER: We didn’t need any more enrichment.

MCDANIEL: Okay.

HOUSER: We didn’t need any uranium for fuel, and we didn’t need any nuclear grade uranium.

MCDANIEL: Do you think that was a political move?

HOUSER: I don’t think it was a political move. I just think we had plenty of fuel.

MCDANIEL: Yeah, yeah.

HOUSER: There would be no real basis to run the gas, to enrich, or to separate.

MCDANIEL: Because they were starting to downgrade our nuclear arsenal.

HOUSER: That’s correct.

MCDANIEL: You know?

HOUSER: We were using some of those to down blend the materials from 90% …

MCDANIEL: For power …

HOUSER: U-235 to 6% U-235.

MCDANIEL: Which was what the fuel rods used for nuclear power plants.

HOUSER: That’s correct.

MCDANIEL: Sure.

HOUSER: Yes.

MCDANIEL: Exactly. That was a bad time for Oak Ridge.

HOUSER: Yes.

MCDANIEL: Lot of people out of work, weren’t they?

HOUSER: My boss came in and said, “Benny, don’t charge any more money to this particular charge number. The centrifuge program has been stopped.”

MCDANIEL: Wow.

HOUSER: He said, “The next phase of things I need to discuss is you need to start thinking about what you’re going to do in the future.” In other words, “You need to think about getting another job, or finding another job.”

MCDANIEL: How old were you then?

HOUSER: Oh, I was probably 45.

MCDANIEL: Which is a … That’s, I mean, you know, you were still …

HOUSER: I wasn’t ready …

MCDANIEL: A young man.

HOUSER: To retire.

MCDANIEL: You weren’t ready to retire. You still had some years left, but that’s tough, you know, when you’re 45 and you’ve done that your whole career, and they basically said, “We’re not going to do this anymore.” It was hard to look at other options. I would imagine it was hard to look at other industries, transferring your skills to other industries, as well.

HOUSER: Well, it was. I was managing a group there during the centrifuge program, and, oh, a couple of weeks later, one of the guys that worked for me came in one morning and said, “Benny, I’ve got an interview at X-10 with,” and he named the fellow’s name, Hal Butler. I don’t know if you’ve met him or not.

MCDANIEL: I grew up with Hal Butler in …

HOUSER: Oh, okay.

MCDANIEL: Kingston. Yeah.

HOUSER: All right, so he goes over there and interviews, and comes back about 1:00, and I said, “Well, how’d it go?” He said, “I’m not going over there. I don’t want the job.” I said, “Well, would it bother you if I called Hal?” He said, “Absolutely not.” I made sure, I said, “Now, you’re sure that you’re willing to do this?” He said, “Yes, I’m sure.” I called Hal and he invited me over for an interview the next day, and he was looking for someone that had a training background, and experience with isotopes. I had taught at Roane State for seven years in night school at that time and worked in radiography.

MCDANIEL: Oh, okay.

HOUSER: We had used isotopes significantly at Y-12, in that period of time. That was my background, and he actually offered me the job while I was being interviewed …

MCDANIEL: Really?

HOUSER: Yes.

MCDANIEL: Sure, sure.

HOUSER: I joined the health physics group at X-10.

MCDANIEL: Oh.

HOUSER: My position was a health physicist in 5505, the transuranic facility there at X-10.

MCDANIEL: Now, tell me what the transuranic facility was.

HOUSER: The researchers worked with elements whose atomic number is higher than 92.

MCDANIEL: Okay. What does that mean?

HOUSER: Well, one of the things it means is that you have to be very careful with the isotopes. The building was under a vacuum all the time, because the release of any of the alpha contamination creates a real problem.

MCDANIEL: It lasts a long time.

HOUSER: It lasts a long time, and it can contaminate anything it comes in contact with.

MCDANIEL: Sure, sure.

HOUSER: We had about 25 scientists there, working in that facility. I worked with an experienced health physicist for several months, and then he eventually retired.

MCDANIEL: What did you do in that facility?

HOUSER: Well, most of my work, at that time, was monitoring our air samples, and watching some of these researchers. We had about 25 glove boxes and researchers would work there, and just to understand what they’re doing and how they’re doing things. They kept one side clean and one side where they worked?

MCDANIEL: Right.

HOUSER: They had good work habits for themselves and others. I monitored there work habits routinely.

MCDANIEL: Sure.

[Editor’s Note: Portion of transcript removed at Mr. Houser’s request.]HOUSER: A couple of things that Hal wanted me to do, fairly soon after I got there was to put together a certification program for the Health Physicist at ORNL [Oak Ridge National Laboratory] and develop a document detailing the buildings ORNL owned that were radiologically contaminated. These are discussed later. So he wanted me to put together a certification program and certify the roughly 100 health physicists that we had. I didn’t ask any questions much then, but it didn’t take me long to realize that the average tenure of these health physicists was 25 years.

MCDANIEL: Really?

HOUSER: They’re looked at as the premier health physicists in the United States or in the world, really.

MCDANIEL: Sure, sure.

HOUSER: Here I am, going to certify them …

MCDANIEL: Right.

HOUSER: And I just walked in, but I put together a program. Each health physicist there worked in their own areas of expertise, and they didn’t move them around from one place to another. We put together a program where the majority of the health physicists could come and talk to all of their buddies and cohorts about their job …

MCDANIEL: About what they did.

HOUSER: About what they did. The health physicists at the laundry who surveyed the clothing coming in and going out, and what did he find in his work?

MCDANIEL: They got to learn about everything.

HOUSER: They enjoyed that process.

MCDANIEL: I bet.

HOUSER: They discussed their jobs with everyone, and then I put together an exam, and they all passed it, for records.

MCDANIEL: Sure.

HOUSER: That’s the way we went through certifying the health physicists …

MCDANIEL: Well, you had the …

HOUSER: There at Oak Ridge.

MCDANIEL: You had the world’s experts talking to the world’s experts.

HOUSER: That’s right.

MCDANIEL: They were probably curious to begin with, about the specifics of somebody else, what they did …

HOUSER: Well, they were.

MCDANIEL: So they enjoyed it.

HOUSER: It was good conversation and a good exchange of information. We didn’t run into anybody that didn’t indicate some interest in what was being shared, and so forth.

MCDANIEL: How long did that process take?

HOUSER: Probably a couple of weeks.

MCDANIEL: Oh, okay.

HOUSER: We didn’t …

MCDANIEL: You did it pretty quickly.

HOUSER: We didn’t do it all day long. We’d set aside a couple hours to meet and go through that list. We didn’t ask everybody to do it. There was some duplication of efforts and so forth.

MCDANIEL: Sure. Sure. Sure.

HOUSER: Then the next assignment … These are in addition to my health physics assignments. Tim Myrick was in charge of a program to look at the buildings at ORNL that needed to be cleaned up from radiation, and wanted some method to prioritize the work, so my challenge was to first identify every building that ORNL owned that was radiologically contaminated.

MCDANIEL: This was at X-10?

HOUSER: At X-10 …

MCDANIEL: Okay.

HOUSER: And Y-12.

MCDANIEL: Oh, and Y-12. Okay.

HOUSER: What it was contaminated with, the isotope, the levels of contamination. How did it get contaminated? I began to put together a program, and went through a method, and it was a six month program, but I learned a lot, and then I provided that list to Tim, and he could see which were the worst buildings and …

MCDANIEL: Sure.

HOUSER: I then helped him make those decisions on what to work on first, if the funds became available.

MCDANIEL: Sure, sure, exactly.

HOUSER: That was another project that I had that was extremely interesting, and I enjoyed it very much.

MCDANIEL: Let me ask you this. Did anything surprise you when you were doing that? Were you surprised at the high level or the low level of …

HOUSER: No.

MCDANIEL: Contamination?

HOUSER: Let me give you an example.

MCDANIEL: Okay, good.

HOUSER: There was a garage down in the eastern end of Y-12, that the walls were clean, but the roof had signs on it, contaminated, and I couldn’t find anybody that had worked there, or anybody that knew how it got contaminated. One of the things, I did go through the DOE health physics program here, also, which was a big help. One of the things I learned fairly soon was to try to get the history of how the contamination got there on anything I’m working with, so I began to ask questions, and finally ended up at our Human Resource Department, getting a list of names of people that had worked in that area …

MCDANIEL: Yeah.

HOUSER: Most of them had retired. I ended up getting in touch with a fellow who said, “Yes, I know the garage you’re talking about, and I’m one of the ones that worked there.” He said, “Benny, when that facility was contaminated, that was years and years ago, and we would have a truckload of contaminated materials and take it out into the woods and dump them.”

MCDANIEL: Yeah.

HOUSER: “That was the way we disposed of those materials at that time.”

MCDANIEL: Exactly.

HOUSER: “Bring that truck in, and pull it in the garage, and spray it with a high-pressure water sprayer, and the contamination splashed up there and attached itself to the ceiling.”

MCDANIEL: You know, it’s amazing that that’s what they used to do.

HOUSER: Yes.

MCDANIEL: I mean, you know … And I guess they didn’t, did they not know better at that time? Did they …?

HOUSER: Well, we didn’t have any disposal places.

MCDANIEL: Right.

HOUSER: They didn’t know about a landfill and things of that nature. That was just the common thing to do, and …

MCDANIEL: Right.

HOUSER: Accepted thing, for a significant number of years.

MCDANIEL: I would imagine, we’re talking, we’re not talking about alpha contamination. We’re talking about …

HOUSER: Well, actually, we are.

MCDANIEL: Really?

HOUSER: That’s what the ceiling was contaminated with, because all they had done was painted it. Well, paint will stop the alpha contamination.

MCDANIEL: Really?

HOUSER: Yes.

MCDANIEL: Huh.

HOUSER: A thin piece of paper will stop it.

MCDANIEL: Really?

HOUSER: Yes.

MCDANIEL: Wow.

HOUSER: It was safe.

MCDANIEL: Yeah.

HOUSER: Nobody got contaminated, but just like I said, we needed to know how it got there, and what problems would we run into in cleaning it up.

MCDANIEL: Sure. That kind of reminds me of the story of hearing them going out to the quarry and just dumping stuff in the quarry …

HOUSER: That’s correct.

MCDANIEL: Because, back then, their motto was, ‘Dilution is the solution.’

HOUSER: Then, you may remember, later on, they came back in the maybe 2000 timeframe, and had barrels, 55 gallon drums, floating, and they’d shoot them.

MCDANIEL: Oh, is that right?

HOUSER: Yeah. Then they ended up having to clean that quarry out.

MCDANIEL: Yeah, yeah, yeah.

HOUSER: That was a significant job.

MCDANIEL: Yeah, exactly.

HOUSER: Anyway, I stayed there, and I mentioned to you about working with a fellow a couple of years before I went over to X-10, we became good friends, so I mentioned that I’d gotten a phone call from him, from China Lake Naval Weapons Center, and I could retire April the 1st, and my phone call came in December. I went out and visited with him, came back, and as I indicated, he had sent me a letter in February offering me the salary that I asked for. My wife and I talked at length for quite a while, and the decision was made that I would accept the job. They were going to let me work out of my home here in East Tennessee, once I got acclimated to the company. Middle of March, I went to China Lake’s Naval Weapons Center in the Mohave Desert, and I got there on Sunday. My wife and daughter were here in Oak Ridge, and we had tickets and arrangements to meet later on, but anyway, I went to work Monday morning and wasn’t real pleased with the way the company was organized, and began to get new information that I didn’t particularly care for.

MCDANIEL: Sure.

HOUSER: Tuesday, I found out I was going to have to pay the state of California 8% of my retirement.

MCDANIEL: Is that right?

HOUSER: Even though I was working in California, but it was coming from Tennessee.

MCDANIEL: Well, that’s not right.

HOUSER: Wednesday, we …

MCDANIEL: Wednesday I’d be on a plane back home, if I were you.

HOUSER: Wednesday, we had more of the same. Thursday, they assigned me to a couple of vendors in New Jersey, and I’d spent a lot of time in New Jersey already, and didn’t really like it, so that afternoon, when I got to the motel, I called my wife and I explained to her that I thought I’d made a serious mistake. Well, she said, “What’s the problem,” and I began to explain to her. I said, “I really don’t want to continue this work.” She said, “Don’t make a quick decision, now. Give yourself plenty of time to think about it,” and I said, “I will, I promise you.” We hung up, I packed my stuff and put them in the car and called her an hour later, and I said, “I’ve thought about it. I’m on my way to Tennessee.”

MCDANIEL: Is that right?

HOUSER: I wrote my friend a note and apologized for any inconveniences that I’d created, and go ahead and send me what was left out of my check I had coming.

MCDANIEL: Sure. Sure.

HOUSER: That was my foray into working on the cruise missile.

MCDANIEL: Well, you just don’t know.

HOUSER: I got home, and, on a Sunday, and Monday I sat down with my wife, and I said, “Honey, I’m going to obligate myself, or dedicate myself, to looking for a job.”

MCDANIEL: Right.

HOUSER: “If I’m not around, I’ll be upstairs in the office, and looking, reading magazines,” so I began to do that. Six weeks later, I had three good job offers. Roane State wanted me to manage their health physics program.

MCDANIEL: Oh, okay.

HOUSER: There’s a company in the same building I was in, the big 10-story building there on the Turnpike, offered me a job.

MCDANIEL: Right.

HOUSER: Then Bechtel offered me a job, so I accepted the job with Bechtel and spent 21 years with them.

MCDANIEL: Oh, is that right?

HOUSER: Yes.

MCDANIEL: Wow.

HOUSER: You’re probably familiar with the FUSRAP program?

MCDANIEL: Yes, FUSRAP. It was cleaning up contaminated sites.

HOUSER: Formerly Utilized Sites Remedial Action Program.

MCDANIEL: That was all over the country, wasn’t it?

HOUSER: All over the country, private industries.

MCDANIEL: Private industries.

HOUSER: Yes.

MCDANIEL: Yeah.

HOUSER: I joined that program, and …

MCDANIEL: Now, was that government funded?

HOUSER: Yes.

MCDANIEL: Okay, so that was the government helping these private industries clean up their messes.

HOUSER: That’s correct.

MCDANIEL: Isn’t that right?

HOUSER: Yeah.

MCDANIEL: Yeah.

HOUSER: Well, the government didn’t clean up sites, all they did was furnish the money.

MCDANIEL: Right.

HOUSER: For example, Mallinckrodt Chemical in downtown St. Louis. Mallinckrodt is a privately owned chemical company, one of the two largest chemical companies in the United States, owned by the family, Mallinckrodt. They made the fuel for the Graphite Reactor, and made the fuel for the first reactor at University of Chicago.

MCDANIEL: Oh, okay.

HOUSER: Soon after General [Leslie] Groves came here, in the Manhattan Project, Mr. Mallinckrodt appeared at a meeting with him, and said, “Who’s going to treat your uranium ore?” He said, “Well, we don’t have anybody.” Mr. Mallinckrodt said, “Mallinckrodt Chemical will treat it for you as long as you want us to treat it.” Mallinckrodt Chemical treated all the ore that came into this country, most of it, from the Belgian Congo, until 1957.

MCDANIEL: Is that right?

HOUSER: Yes, and it went to Mallinckrodt Chemical in downtown St. Louis, and contaminated their facilities a lot.

MCDANIEL: Now, let me ask you a question, just because I’m interested in that. The uranium ore came in to Mallinckrodt, and then you said they treated it chemically. What did they do?

HOUSER: Well, the first thing they, let me share this, and maybe it’ll help you understand just a little bit, but uranium ore is a metal in the ground just like other precious metals.

MCDANIEL: Yep.

HOUSER: We have mines here in the United States that produce uranium ore, but it’s about 10% uranium. The rest of it’s soil and so forth.

MCDANIEL: I see.

HOUSER: Canada has some ore that is about 20% at the most. In the Belgian Congo, they have some mines there that contain 65% pure uranium.

MCDANIEL: Wow.

HOUSER: 95% of our uranium ore came from the Belgian Congo …

MCDANIEL: Okay.

HOUSER: Until ’85.

MCDANIEL: Right.

HOUSER: All the ore would come in and go to Mallinckrodt, and then in 1957, they built the facility in Mound, Ohio, between Cincinnati and Dayton, and the government got into creating the uranium hexafluoride themselves.

MCDANIEL: Oh, I see. That’s what they were doing. Mallinckrodt was creating uranium hexafluoride.

HOUSER: That’s correct.

MCDANIEL: I see.

HOUSER: They would put it in the appropriate tanks. I’m sure you’ve seen some tanks that that uranium hexafluoride is in, and ship it to Y-12 or K-25, during the Manhattan Project.

MCDANIEL: Right, right. Okay.

HOUSER: Then it would be put into a piece of equipment, if you can imagine an oversized casket, and the lid is open on the casket, and you lower this tank down in there. The tank is at ambient temperature, and the uranium that’s in it is 65% full, and it’s a solid.

MCDANIEL: Right.

HOUSER: Then they’d close it, it’s called a freezer sublimer, and heat it up to 200 degrees. Uranium becomes a gas at 200 degrees …

MCDANIEL: Oh.

HOUSER: And then flow it into the first cascade.

MCDANIEL: That’s how they would …

HOUSER: That’s how they would get it into the cascade.

MCDANIEL: Cascade.

HOUSER: Then we had a compressor and a converted, a compressor and a converter.

MCDANIEL: Right.

HOUSER: It went through …

MCDANIEL: On and on.

HOUSER: The entire line, and then at the end of the line, they would just reverse the process and put it into a freezer sublimer and cool it down, and that’s it.

MCDANIEL: Wow. Wow.

HOUSER: Now there’s another little side of the story that a lot of people are not aware of right now, but we did find a use for U-238 in a couple of areas. One was the ends of bullets, large bullets. You could put it on the end of those or use the depleted uranium, for shielding in reactors. The U.S. also made blocks of U-238 to put in wings of aircraft to balance them.

MCDANIEL: So people will understand: Natural uranium is 99.3% U-238 and .7% U-235.

HOUSER: That’s correct.

MCDANIEL: Right.

HOUSER: Then you either go to a 90% level, U-235 for weapons …

MCDANIEL: Yeah.

HOUSER: A 6% level for nuclear fuel.

MCDANIEL: Sure, exactly.

HOUSER: Yes.

MCDANIEL: Okay.

HOUSER: Here’s the bottom line to my story.

MCDANIEL: Okay.

HOUSER: Today, as we speak, we’ve got about 7,000 containers of U-238 sitting in Portsmouth, Ohio, that the government cannot figure out what to do with.

MCDANIEL: Is that right?

HOUSER: That’s correct.

MCDANIEL: Oh, wow. My goodness.

HOUSER: Anyway …

MCDANIEL: That was an example of the kind of the FUSRAP projects we worked on.

HOUSER: That’s correct. Enrico Fermi had 45 labs up at the University of Chicago that he was using to study plutonium. We went up and cleaned all those up.

MCDANIEL: Is that right?

HOUSER: Columbia University on Broadway in the Borough of Manhattan had about 1,200 tons of ore in a warehouse there. They actually had 5,000 people employed there in those warehouses in 1939, doing research with uranium. It contaminated the floor in that warehouse, so I believe about four of us, and several rad technicians and some construction workers went up and cleaned that up.

MCDANIEL: I bet you did a lot of work in New Jersey, didn’t you?

HOUSER: Yes, but that’s a different situation. Let me just talk about it briefly.

MCDANIEL: Okay, go ahead. Sure, go ahead.

HOUSER: The problem in New Jersey was thorium.

MCDANIEL: Right.

HOUSER: Thorium is used in Coleman lantern mantles, that’s what makes them burn so bright.

MCDANIEL: Yep.

HOUSER: We had several companies in that area of New Jersey that produced these mantles. Also most health physicist keep a mantle laying on their desk that he puts his instrument on periodically, just to see if it’s working.

MCDANIEL: Is that right?

HOUSER: The mantel is still encased in the plastic, so it’s not contaminating anything. Anyway, these companies were separating that thorium for this lantern mantle, visually, and certainly wasn’t getting all the thorium out of the soil. But unbeknownst to them and other people, it ended up, the byproduct was a nice, loamus clean soil out behind the building in a pile. Then it rained and would wash that soil into ditch lines.

MCDANIEL: Yep.

HOUSER: People would take that material home and put it in their flower beds and so forth. In Montclair, New Jersey, we found eight homes built on contaminated soil, and put the people in apartments for two years …

MCDANIEL: Is that right?

HOUSER: While we raised their house up, took all the contaminated soil out from under it, put clean soil back in, new foundations, and let them come back in two years.

MCDANIEL: Wow.

HOUSER: Anyway, Bechtel had rad technicians that would, what we call in the discipline, swing a meter, walking those ditch lines …

MCDANIEL: Swinging a meter.

HOUSER: Bechtel would clean out the ditch line and store the soil there in Wayne, New Jersey, and keep it fenced in. Then, along toward the end of the program, they put together a shipping program to ship that material from Patterson, New Jersey. We had to build a facility in Patterson where we could drive a dump truck up to the boxcar, dump the dirt in, wrap it up appropriately, and ship it to Clive, Utah, to be buried in the waste disposal out there.

MCDANIEL: Wow.

HOUSER: The majority of the work in New Jersey was associated with thorium.

MCDANIEL: With thorium, yeah.

HOUSER: If you look it up on the internet, and I’ve tried, basically the only thing I can see is it was an “environmental nightmare.”

MCDANIEL: Right. Right, exactly. It was an “environmental nightmare.”

HOUSER: Yeah.

MCDANIEL: You worked at FUSRAP for, what’d you say, 13 years?

HOUSER: Yes, for about 13 years.

MCDANIEL: Oh, yeah. Okay.

HOUSER: 13 years.

MCDANIEL: Were you based out of Oak Ridge?

HOUSER: Yes.

MCDANIEL: Okay.

HOUSER: I had an office in Oak Ridge.

MCDANIEL: Was the FUSRAP headquartered in Oak Ridge?

HOUSER: Yes.

MCDANIEL: Okay, that’s what I was thinking, it was.

HOUSER: Yeah.

MCDANIEL: Yeah.

HOUSER: Then I was going to retire in ’98, but Bechtel had won the contract to clean up K-25.

MCDANIEL: Oh, okay.

HOUSER: They asked me to stay three months to help get the Environment, Safety, and Health paperwork and procedures in place.

MCDANIEL: Sure.

HOUSER: I stayed and spent that time, then I didn’t work for about a year. The FUSRAP manager wanted an audit done from his level down to the janitor to be sure we had good communications and procedures. So they asked me to come join four other people, and we did an audit of the three facilities, and all levels of each facility, to ensure the procedures were adequate, and there wasn’t any problem. Then my health and safety manager, Dr. Dennis Stephenson, asked me if I’d just stay and become a consultant, so I did. I stayed there until 2008, working no more than 32 hours and no less than eight each week.

MCDANIEL: Right.

HOUSER: That’s kind of a summary of my career.

MCDANIEL: Wow.

HOUSER: I don’t know of a person that could have spent his life in loving to work, loving his work as much as I did. Then, today, I work at the Museum of Science and Energy. I’m also a DOE tour guide.

MCDANIEL: Take people on the bus?

HOUSER: Yeah.

MCDANIEL: You take people on it …?

HOUSER: Yeah. The tour guide talks a lot about the Manhattan Project.

MCDANIEL: Sure.

HOUSER: About the things that happened during the Manhattan Project …

MCDANIEL: Yeah, yeah.

HOUSER: In detail. It’s a three-hour tour, so we talk about two hours and 45 minutes.

MCDANIEL: Exactly.

HOUSER: That just fit right in with my interest and what I’ve done and what I’ve been doing with my life, so I’ve just been a very fortunate individual …

MCDANIEL: Right.

HOUSER: To enjoy their work as I have.

MCDANIEL: What’s the most unusual question you’ve ever had on one of those tours, or the most memorable question?

HOUSER: Oh …

MCDANIEL: I guess I should ask …

HOUSER: No, that’s a reasonable question. We don’t get a lot of questions, but …

MCDANIEL: Because you all are talking the whole time.

HOUSER: Well, for example, the Spallation Neutron Source. They seem to have difficulty understanding what happens when the proton bombards the mercury target.

MCDANIEL: Right.

HOUSER: And the neutrons are released. They don’t understand spallation.

MCDANIEL: Right.

HOUSER: I gave them Benny’s explanation of spallation. We’d park near a concrete wall, a new wall at the Spallation Neutron Source.

MCDANIEL: Yeah.

HOUSER: I told the tourists, “If this was 50 years ago and that wall was 30 years old, and you gave me a rock about the size of a baseball, and I threw that rock as hard as I could against that old concrete wall, concrete would be “spalled” off.

MCDANIEL: That’s right.

HOUSER: Off.

MCDANIEL: Little pieces would just go every direction.

HOUSER: All different sizes of pieces, and you can imagine these protons striking the mercury and the neutrons of all different energy levels being spalled off.

MCDANIEL: That’s it.

HOUSER: They seemed to think that scratched their itch, as far as …

MCDANIEL: Well, sure.

HOUSER: Understanding …

MCDANIEL: Yeah.

HOUSER: How that worked.

MCDANIEL: The Spallation Neutron Source is a, you know, it is kind of complicated until you understand the very basics of what you just explained, you know. What I want to know is how they catch them. They have to catch those neutrons to be able to do their experiments.

HOUSER: That’s the thing about it. None of us have ever been allowed to see the equipment or been taken in. We’ve been in most of the facilities at ORNL but we’ve never gone into the Spallation Neutron Source Target Facility.

MCDANIEL: I was in the tunnel when they were building it.

HOUSER: Okay. Okay.

MCDANIEL: It looked like something from a, well, I don’t know what, but it was a lot of copper, and a lot of interesting looking stuff.

HOUSER: One of the points that I make about that beam line is that it is perfectly level. It doesn’t follow the curvature of the Earth.

MCDANIEL: Yeah, yeah, exactly.

HOUSER: To my understanding, they are in the process of designing another facility now, another target facility.

MCDANIEL: Right, right.

HOUSER: That’ll double their capacity of researchers.

MCDANIEL: Sure, sure. What do you discover about people who go on the tour? Do they know very much to begin with? Is this all just new and fascinating, or are there some people that …?

HOUSER: I can answer that question very easily. We go to the Graphite Reactor, and we go in and sit down and get comfortable, and the first question I ask, every tour, “How many of you understand how a reactor operates?” Seldom do I get a hand.

MCDANIEL: Right.

HOUSER: One time I recall a fellow sticking his hand up, and I said, “What makes you understand about a reactor?” He said, “I work for the Nuclear Regulatory Commission.” Well, that gave me an opportunity to tell everybody about the Nuclear Regulatory Commission.

MCDANIEL: Yeah, exactly.

HOUSER: Another lady taught physics. I take them through a process of how the reactor works.

[Editor’s Note: Portion of transcript removed at Mr. Houser’s request.]HOUSER: Then I add a little caveat. I said, “It’s my thought, and has been for years, that the Atomic Energy Commission made a mistake by not, when we started in the nuclear business, not forcing every high school student, as a senior, to take a course in radiation protection.”

MCDANIEL: Right.

HOUSER: I think we would have been a much different nation, in our ideas and attitudes toward radioactivity and nuclear energy, and so forth.

MCDANIEL: Because people would have had a basic understanding of it, and wouldn’t have been as afraid of it.

HOUSER: That’s correct. You’re exactly right. Anyway, a lot of them really seem to appreciate that simple explanation.

MCDANIEL: Sure, sure.

HOUSER: That’s what I’ve found unique about the tourists knowledge of radiation. Very seldom do I ever see a hand.

MCDANIEL: Are most of the people like within driving distance of us, or do you have them from all over the world?

HOUSER: No. If you look at our list of tourists, about three fourths of them are from out of state.

MCDANIEL: Oh, is that right?

HOUSER: Yes.

MCDANIEL: Okay.

HOUSER: And a fourth of them from Tennessee. I found that interesting.

MCDANIEL: Yep.

HOUSER: Last year, and I’m not sure of the number right now, but I believe we had about 6,000 tourists come last year.

MCDANIEL: Is that right?

HOUSER: Come to participate in the tours.

MCDANIEL: Is that right?

HOUSER: The bus we use is a 34 passenger bus, owned by ORNL.

MCDANIEL: Yeah.

HOUSER: 90% of the time, it’s full.

MCDANIEL: Is that right?

HOUSER: Yeah.

MCDANIEL: Wow.

HOUSER: We’re running five days a week now, in June, July, and August …

MCDANIEL: Yeah, yeah.

HOUSER: Then we taper off in the fall and start again in the spring.

MCDANIEL: Yeah.

HOUSER: One of the big things the museum has done that helped a lot is we allow people to sign up for tours online now …

MCDANIEL: Yep.

HOUSER: For about half of them, and then the other half is first come, first serve.

MCDANIEL: Right.

HOUSER: It continues to grow in interest, the tours and the number of people that want to go and so forth.

MCDANIEL: Do you think that the national park has had any impact on that, with Oak Ridge becoming a national historical park?

HOUSER: Well, I think it has, from a standpoint of people like to come by. A lot of people are fans of national parks, and go to different ones, so they want to visit here just to document they’ve been here.

MCDANIEL: Right.

HOUSER: We have those type people, and of course you know we both share the museum now.

MCDANIEL: Yeah, exactly, for now.

HOUSER: Yeah. Anyway, the National Park Service, I think, has contributed to the interest, but a lot of people come just to get their documentation signed and pick up some leaflets or something …

MCDANIEL: Sure, sure.

HOUSER: Just to show that they visited the Oak Ridge National Park.

MCDANIEL: Right, right.

HOUSER: I think it’ll really be nice if we follow through with a plan to rebuild a corner of that K-25 facility.

MCDANIEL: Yep. Yep. That is true. That is true. What else? Anything else you want to talk about?

HOUSER: No. I’ve kind of touched on the highlights of my career. Like I said, I’ve been a very fortunate individual. I’ve appreciated all the people that I’ve worked with and for, and all the people that have been willing to share their information with me.

MCDANIEL: Sure.

HOUSER: I’ve just been a very lucky fellow, and I’m enjoying my volunteer work now.

MCDANIEL: Was there ever a point, besides your venture out to the desert, that you thought about leaving and doing something else?

HOUSER: While I was at Y-12, Chicago Bridge and Iron had a facility in Memphis testing nuclear pressure vessels in the Mississippi River, and they invited me to come out and interview, and manage their radiography program. I didn’t go. Then there was a program starting, I believe in Jacksonville, to produce floating nuclear reactors, Tenco and Westinghouse. These reactors were small reactors, and they’d be on a barge, and they would build them there in Jacksonville and build a sea wall to keep the water smooth where they were floating the barge and working with it, and provide reactors up and down the East Coast. They invited me down, and the first thing they wanted me to do was to put a radiation protection program in numerous junior colleges throughout Florida.

MCDANIEL: So they could train people …

HOUSER: So they could train people …

MCDANIEL: To have workers.

HOUSER: To go to work there.

MCDANIEL: Yeah.

HOUSER: I said, well, that I could do that, and then put a program in place there and manage it, and I said, “Well, there’s one caveat here now, and I want you to be honest with me. Has the NRC [Nuclear Regulatory Commission] approved this?” They said, “No, but we think they will.” I said, “Well, when you get it approved, let me know, and I’ll give you an answer.”

MCDANIEL: Right.

HOUSER: They never called.

MCDANIEL: They never called you. Oh, well. My goodness.

HOUSER: It would have been an interesting job, and …

MCDANIEL: Yeah.

HOUSER: I might have considered it …

MCDANIEL: Sure.

HOUSER: Pretty good, but …

MCDANIEL: Well, well, Mr. Houser, thank you for coming in.

HOUSER: Thank you for inviting me.

MCDANIEL: Thank you for talking about your career, all the interesting things that you’ve done.

HOUSER: It’s something I enjoy doing, talking about it. I don’t hesitate, as you might notice, to do it. I appreciate the opportunity, and I believe I mentioned to you, I did write indexes for about 150 of these interviews.

MCDANIEL: Indexes for these interviews?

HOUSER: Yes.

MCDANIEL: Yeah.

HOUSER: We …

MCDANIEL: Well, now you can add yours to that.

HOUSER: That’s pretty neat, I think.

MCDANIEL: Well, good. Thank you so much. I appreciate you.

HOUSER: All right, you’re quite welcome, and I appreciate you.

[End of Interview][Editor’s Note: Portions of this transcript have been edited at Mr. Houser’s request. The corresponding audio and video components have remained unchanged.]